Phello ea khase ea Flue

Kenyelletso e Khutšoanyane ea Theknoloji ea Semi-dry Desulfurization bakeng sa Sintering Furnace Flue Gas in Iron and Steel

Ka 1986, Wuxi Linzhou Drying Equipment Co., Ltd, e sebelisa theknoloji e kholo ea ho omisa, ka kopanelo le Southwest Electric Power Design Institute, Nanjing Institute of Forestry & Chemical Industry, Univesithi ea Chongqing le litsi tse ling tsa lipatlisiso tsa mahlale, e ile ea nka sehlooho se khethehileng sa "Lipatlisiso mabapi le theknoloji e phahameng ea sebabole e potolohang ka rotary "theknoloji ea ts'ireletso ea tikoloho ea lilemo tse hlano" morero oa ho etsa lipatlisiso.Ka mor'a lilemo tse 'maloa tsa lipatlisiso, sete e feletseng ea thepa ea mokhoa oa Sechaena e se e thehiloe Sichuan Baima Power Plant le li-index tse reriloeng esale pele tsa tekheniki li phethiloe ka botlalo, ho etsa hore lipatlisiso tsena tsa theknoloji ea desulfurization e be mohato o moholo oa ho sebelisa indasteri.

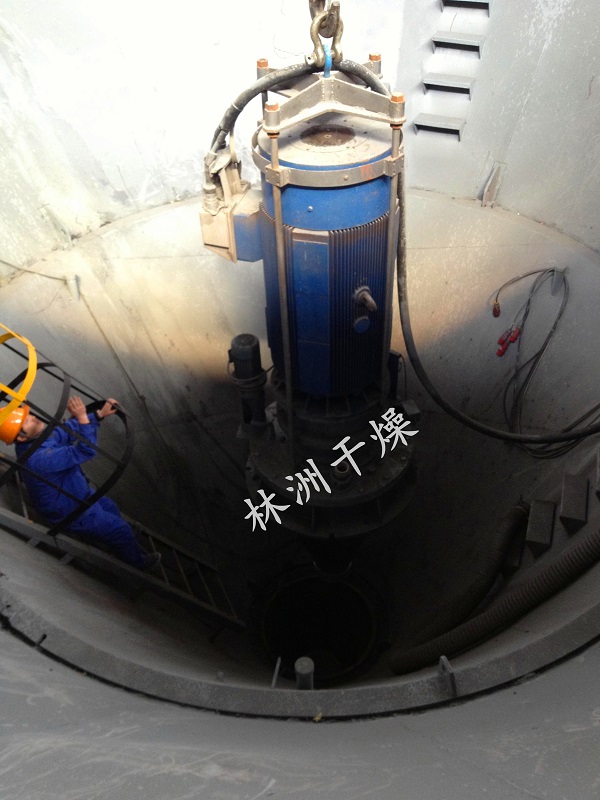

Ka 1998, theknoloji ea semi-dry flue flue desulfurization e ile ea thathamisoa e le e 'ngoe ea litaba tsa sebaka seo. Wuxi linzhou drying equipment co., ltd, ka kopanelo le setsi sa meralo ea motlakase e ka boroa-bophirima, Setsi sa Nanjing sa meru le indasteri ea lik'hemik'hale, univesithi ea Chongqing le litsi tse ling tsa lipatlisiso tsa mahlale, li nkile morero oa "liteko tsa indasteri le lipatlisiso mabapi le lisebelisoa tsa semi-dry flue flue desulfurization". nomoro ea konteraka e ne e le SPKJ005-02 mme nomoro ea khoutu ea morero e ne e le j-16ikj98.Bophahamo ba khase ea flue e hloekisitsoeng ke 400,000 Nm3/h.Wuxi linzhou drying equipment co., ltd. ke eona e ikarabellang haholo-holo bakeng sa likarolo tse ka sehloohong tsa morero: yuniti e phahameng ea centrifugal atomizing e nang le lithane tse 45 tsa spray ea metsi ka hora.Ka mor'a tlhahiso e atlehileng ea liteko, e ile ea kenngoa ts'ebetsong Guizhou Chuanheng Chemical Co., Ltd. ka 2005. Motlakase oa motlakase o na le matla a 312KW le boholo ba spray volume / h.50 t. Thepa e sebetsa ka matla a feletseng selemo ho pota ka tlhahiso ea letsatsi le letsatsi ea phofo e omileng ea lithane tse 600. Ho fihlela joale, lihlopha tse ngata tsa lihlopha li kentsoe tšebetsong tšimong ea indasteri e kholo ea lik'hemik'hale. Liyuniti li sebetsa ka mokhoa o tsoelang pele ho pholletsa le selemo ka ts'ebetso e tsitsitseng le botsitso ba lisebelisoa tse tšepahalang.

Ha yuniti ea 45T/h centrifugal atomizing e ntse e ntlafatsoa le ho hlahisoa, sehlopha sa lipatlisiso le nts'etsopele se boetse se entse lipatlisiso mabapi le moralo oa tora ea semi-dry desulfurization, tlhahlobo ea phallo ea phallo toreng ea desulfurization le karolo ea karoloana. Sehlopha sa lipatlisiso le nts'etsopele se boetse se hlophisitsoe ho metha le ho sekaseka lisebelisoa tse tsoang kantle ho naha ho tsoa K'hamphaning ea NIRO ea Denmark, 'me se tsebisitse lisebelisoa tse nepahetseng tsa software bakeng sa moralo oa mochini o futhumatsang moea o chesang le tora ea desulfurization ea Khamphani ea NIRO. merero ea semi-dry desulfurization. Ha re sheba boemo ba ho reka, o na le melemo e meholo ka theko, empa o lahliloe ka lebaka la khaello ea ts'ebetso ea khoebo. Ka hona, ka lilemo tse ngata, boholo ba lits'ebetso tsa semi-dry desulfurization tse sebelisoang lifemeng tsa motlakase tsa lapeng ke lisebelisoa tse tsoang kantle ho naha.

Lilemong tsa morao tjena, ka ntlafatso ea litlhoko tsa naha ea ts'ireletso ea tikoloho, khase ea flue desulfurization ea sintering sebōpi ka lichelete tsa tšepe, e le sepheo se ka sehloohong sa taolo ea naha ka mor'a hore ho felloa ke matla ha khase ea flue ea limela tsa matla, e ikarabella bakeng sa hoo e ka bang 11% ea likhase tsa naha tsa SO2 le tse ling tse silafatsang sepakapaka indastering ea matla a tšepe, boemo ba bobeli ba CO2, CO2, lerōle la SO2 feela le litšila tse ling tse hlahisoang ts'ebetsong ea sintering li etsa 40% ~ 60% ea likhase tsa selemo le selemo tsa indasteri ea tšepe le tšepe. Ka hona, ho bohlokoa haholo bakeng sa nts'etsopele e tsitsitseng ea indasteri ea tšepe le ea tšepe le ntlafatso ea tikoloho ea tikoloho ho laola ho ntšoa ha litšila tse tsoang ho sintering flue gase le ho etsa phetoho ea thekenoloji ea desunterfurization flue flue.

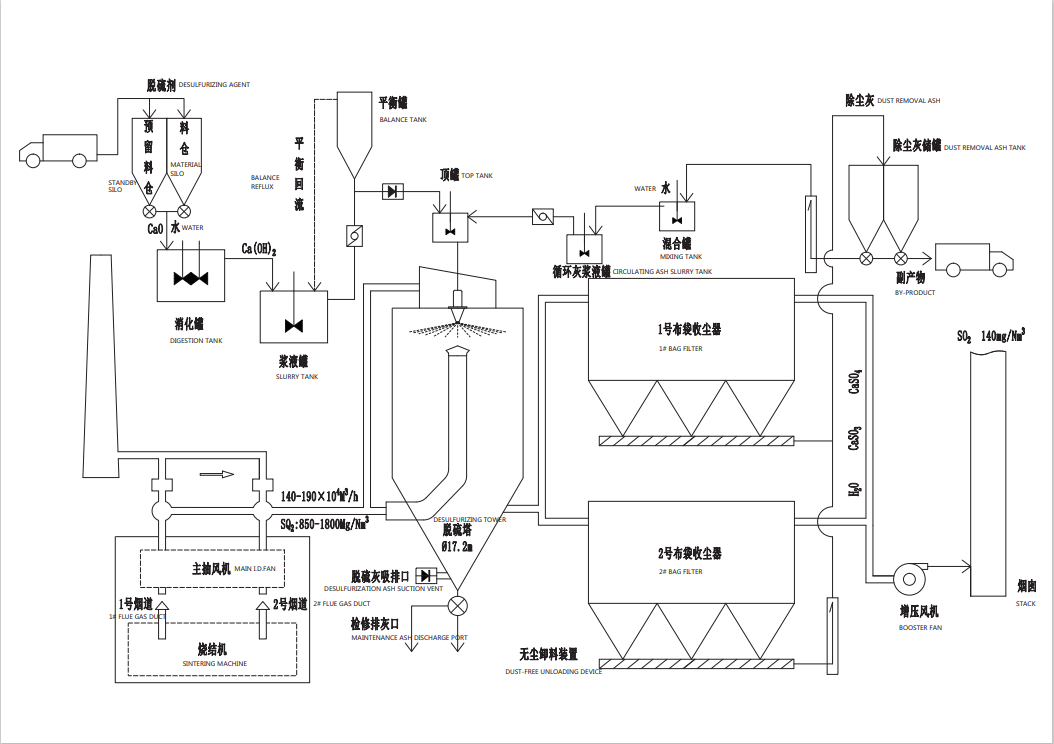

Ha re bua ka basebelisi ba fetang 10 ba ts'ebetso ea sintering flue flue desulfurization le likarolo tse ngata tsa meralo ea desulfurization joalo ka Shougang, Jinan, Baosteel le Tangshan, mokhoa oa ho omisa semi-dry sintering flue flue desulfurization o sebelisoa haholo. The spray drying semi-dry desulfurization process e na le litšobotsi tsa theknoloji e butsoitseng, phallo e bonolo ea ts'ebetso, ts'epo e phahameng ea sistimi le tse ling tse joalo. Sekhahla sa desulfurization se ka fihla ho feta 85%, SO2 emission concentration ka mor'a desulfurization ≤100mg/Nm3, le lerōle emission concentration ≤50mg/Nm3..Ts'ebetso e na le mefuta e itseng ea kopo (8%) United States le linaheng tse ling tsa Europe Bophirimela.

Lilemong tsa morao tjena, Wuxi Linzhou Drying Equipment Co., Ltd. e kopanetse ka kopanelo lipatlisiso tsa nts'etsopele ea phetoho ea khase ea flue desulfurization ea mochini oa sintering ka lifemeng tsa tšepe ka Nanjing Forest Products Chemical Research Institute, Jinan Iron le Steel Group, Univesithi ea Dalian ea theknoloji le litsi tse ling:

Ka kopanelo le Dalian University of Technology, ho ile ha thehoa setsi sa liteko bakeng sa ho tlosa khase e ntšoang ka har'a sebōpi sa sintering Chongqing Iron and Steel Group.

Moralo oa tora ea desulfurization ea projeke ea mochini oa 320m2 sintering desulfurization ea Jinan iron and steel group co., Ltd. le teko ea lapeng ea yuniti ea atomizing ea lithane tse 45 ea lehae e fihletse phello e ntle ea ho fetoha lipakeng tsa thepa ea lapeng le thepa e tsoang kantle ho naha.