Resource Treatment of Black Liquor from Papermaking by Spray Drying

Kaha boholo ba lisebelisuoa tse tala bakeng sa pulping Chaena ke lisebelisoa tse tala tsa faeba e seng lehong (e ikarabellang ho feta 50%), mekhoa ea ho hlaphoheloa ea alkali le asiti e sebelisoa bakeng sa ho phekola joala bo botšo libakeng tse ngata tsa pampiri. Leha ho le joalo, ka lebaka la ts'ebetso e mpe ea ho hloekisa metsi ea makhasi a joang, lisele tse ngata tse fapa-fapaneng tsa joala ba batsho, li-viscosity tse phahameng le likahare tse phahameng tsa silicon tsa joala ba batsho, phello ea sebele ea ts'ebetso ea mokhoa oa ho hlaphoheloa ha alkali e futsanehile, tekanyo ea ho hlaphoheloa ha alkali e ka bang 60% feela, katleho e tlaase ea mocheso, litšenyehelo tse phahameng tsa ts'ebetso le tsamaiso e thata. Ka hona, ho thata ho rarolla bothata ka botlalo ba tšilafalo ea joala bo botšo semeleng sa makhasi a joang. Motheong oa lipatlisiso le nts'etsopele ea ho omisa le ho ts'oara mouoane ka lilemo tse ngata, 'me ho kopantsoe le moralo le boiphihlelo ba ts'ebetso ea ho hlahisa sistimi e le 'ngoe ea mouoane le khatello ea joala bo ntšo linaheng tsa kantle, k'hamphani ea rona e sisintse le ho kenya tšebetsong ts'ebetso ea ho ntša tšilafalo ea zero ea kalafo ea joala bo botšo.

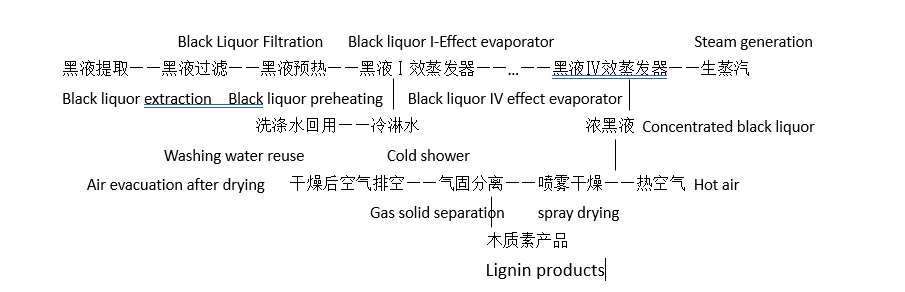

Metsi a koaletsoeng le joala bo botšo bo koalehileng bo tsoa ho mouoane, condensate e ka sebelisoa e le metsi a ho hlatsoa, ha joala bo botšo bo kentsoeng bo kena ka har'a spray. Nakong ea ts'ebetso ea ho omisa, palo ea lerōle le tsoang tsamaisong ea ho omisa e ka tlaase ho 100 ~ 150 mg / m3, e ka finyellang litekanyetso tsa naha tsa tlhahiso. Ha ho na metsi a litšila a tsoang, 'me lihlahisoa tsa lignin li fumanoa ka nako e le' ngoe. Ts'ebetso eohle ea kalafo ea tahi e ntšo ha e thata ho e fumana, 'me ha ho na khase e litšila le litšila tse tsoang ts'ebetsong eohle, e le ho fihlela sepheo sa ts'ilafalo ea ts'ilafalo ea pheko ea joala bo ntšo. Pampiri e etsang joala e ntšo e etsoa lihlahisoa tsa lignin bakeng sa tšebeliso e felletseng. E sebelisoa haholo ho fokotsa metsi a konkreite, li-slurry dispersant tsa metsi a mashala, emulsifier ea asphalt, li-ceramics, li-additives tsa tšebeliso ea seliba sa oli, joalo-joalo, e le ho felisa tšenyo ea tikoloho, ho theha tsela ea tsoelo-pele e lumellanang le tikoloho, ea tlhaho le e lumellanang, 'me e le kannete ho hlokomela bonngoe ba melemo ea moruo, melemo ea tikoloho le melemo ea sechaba.

Ts'ebetso ea ho ntša metsi a se nang letho ha ho ntšoa joala bo botšo

1. Boitsebiso:ho etsa pampiri joala bo botsho le joala bo kgubedu

2. Thempereichara e kenang moeeng:280 ℃ ~ 430 ℃

3. Mocheso oa mocheso oa moea:110 ℃

4. Phallo ea phofo e omileng:1000 lik'hilograma / H ~ 4000kg / h

5. Litaba tse tiileng:40% ~ 50%

6. Mohloli oa mocheso:setofo se chesang se chesang ka mashala se nang le kamore ea ho phomola, mouoane o chesang haholo, joalo-joalo (e ka nkeloa sebaka ho latela maemo a bareki)

7. Mokhoa oa atomization:high speed centrifugal atomizer e amoheloa

8. Mokhoa oa ho futhumatsa:setofo se chesang se chesitsoeng ka mashala (se nang le kamore e mekato e mene ho thibela Mars ho kena)

9. Ho hlaphoheloa ha lintho tse bonahalang:ho tlosoa ha lerōle la leholiotsoana la pele le ho tlosoa ha lerōle la ho hlatsoa metsi a metsi a bobeli li amoheloa, ka sekhahla sa ho hlaphoheloa sa 99.8%, se tsamaellanang le litekanyetso tsa naha tsa Moaho.

10. Ho amohela:ho amoheloa ha bohareng ho amoheloa. Botlaaseng ba tora le phofshoana e ntšitsoeng ho moqokelli oa lerōle la leholiotsoana li romelloa ka mokhoa o ts'oanang ho sistimi ea phepelo ea moea Ho paka ho tla etsoa ka tlung ea polokelo ea pokello ea liphutheloana tse khethiloeng.

11. Taolo ea motlakase:Taolo ea lenaneo la PLC e amohetsoe. (taolo ea othomathike ea mocheso o kenang moeeng, mocheso o tsoang moeeng, mocheso oa oli le alamo ea khatello ea oli ea atomizer le pontšo e mpe ea khatello tora)